Tips and Tricks For Removing a Stripped Allen Screw Easily

Have you ever faced the frustration of dealing with a stripped Allen screw that just won’t budge? It’s a common predicament in the world of DIY projects and can bring your progress to a screeching halt. But fear not! This guide will walk you through several effective methods to remove that stubborn Allen screw, restoring your workflow and perhaps even saving your day.

Understanding Why Allen Screws Become Stripped and How to Prevent It

Stripped Allen screws can turn what should be a simple task into a frustrating challenge, halting progress, but it should never stumble your motivation. This often occurs due to using an incorrect size of Allen key or excessive force.

To prevent this, always ensure that the Allen key fits snugly in the screw head, and apply consistent, moderate force. Lubricating the screw beforehand can also reduce the risk of stripping, making future removals smoother.

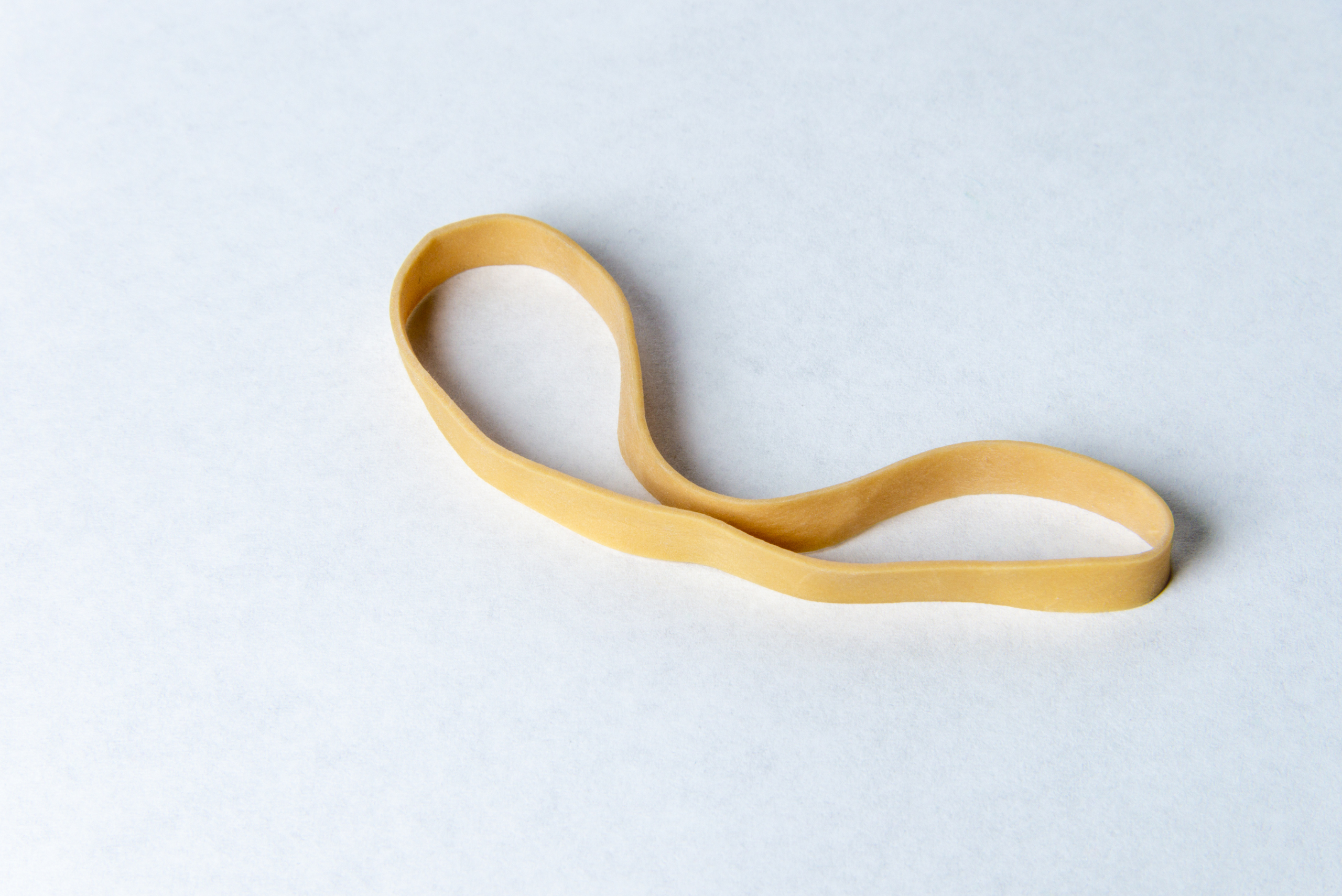

The Rubber Band Trick – A Quick and Handy Solution

One of the simplest and most accessible methods to remove a stripped Allen screw is the rubber band trick. Place a wide rubber band between the screw head and the Allen key. This provides extra grip and can allow the key to catch onto the stripped areas. Press down firmly and turn slowly; with a bit of luck, the screw will begin to move.

Using a Flathead Screwdriver – Leveraging Shape and Force

If the rubber band trick doesn’t work, reaching for a flathead screwdriver might be your next best option. Find a screwdriver that fits as tightly as possible into the stripped head. You might need to tap it gently with a hammer to set it in place. Once secured, slowly turn the screwdriver to loosen the screw. This method uses the broader surface area of the flathead to gain traction inside the stripped head.

Drilling Out the Screw – When All Else Fails

As a last resort, drilling out the screw may be necessary. Start with a small drill bit and drill a hole directly into the center of the screw head. Gradually increase the size of the bit until the screw head can be removed from the body. This method should be used sparingly, as it can damage the material around the screw.

Employing a Screw Extractor for Stubborn Cases

For screws that are deeply embedded and stripped, a screw extractor can be a game-changer. This tool works by drilling a reverse thread into the screw. As you turn the extractor, it grips tighter and eventually pulls the screw out. It’s a specialized tool that’s worth having on hand for those particularly challenging situations.

Alternative Methods and Tools to Consider

There are various other tools and methods that can also be effective in removing stripped screws. One such tool is a pair of locking pliers, which can clamp down on the head of the screw, allowing you to twist it out. Another method involves using a rotary tool with a cutting disc to carve a new, deeper slot in the screw head for a flathead screwdriver to fit into.

Related Articles

- How to Loosen a Bolt That Won’t Budge

- Stripped Screw Hacks – Effortless Solutions for Stubborn Screws

- How to Unscrew a Tight Screw and Deal with Stubborn Fasteners

While a stripped Allen screw can be a nuisance, having the right techniques and tools at your disposal can greatly simplify the removal process. Remember, patience and the right approach are your best allies in overcoming this common DIY hurdle. Always wear protective gear when using tools like drills and rotary tools, and ensure your workspace is safe. With these tips, you’ll be ready to tackle even the most stubborn screws in your future projects.

Ready to start your next project? Join our DIY community to receive tool tips, how-to guides, and exclusive creative insights. Subscribe to the ManMadeDIY newsletter now! Click here to unlock a world of hands-on inspiration.