Tips and Tricks For How to Use a Screw Extractor

When faced with the frustrating predicament of a stripped or broken screw, the task of removal can seem daunting, if not impossible, without causing damage to the surrounding material. Enter the screw extractor – a tool ingeniously designed to tackle this very challenge.

This article will guide you step-by-step through the process of using a screw extractor, from selecting the right size for your task to the final twist that frees the troublesome screw. Whether you’re a DIY enthusiast, a professional handyman, or someone simply looking to rescue a project, understanding how to wield a screw extractor can save not just your materials but also time and peace of mind.

Identifying the Right Type of Screw Extractor for Your Needs

Choosing the correct screw extractor is crucial for effectively removing a broken or damaged screw without causing further damage to the material around it.

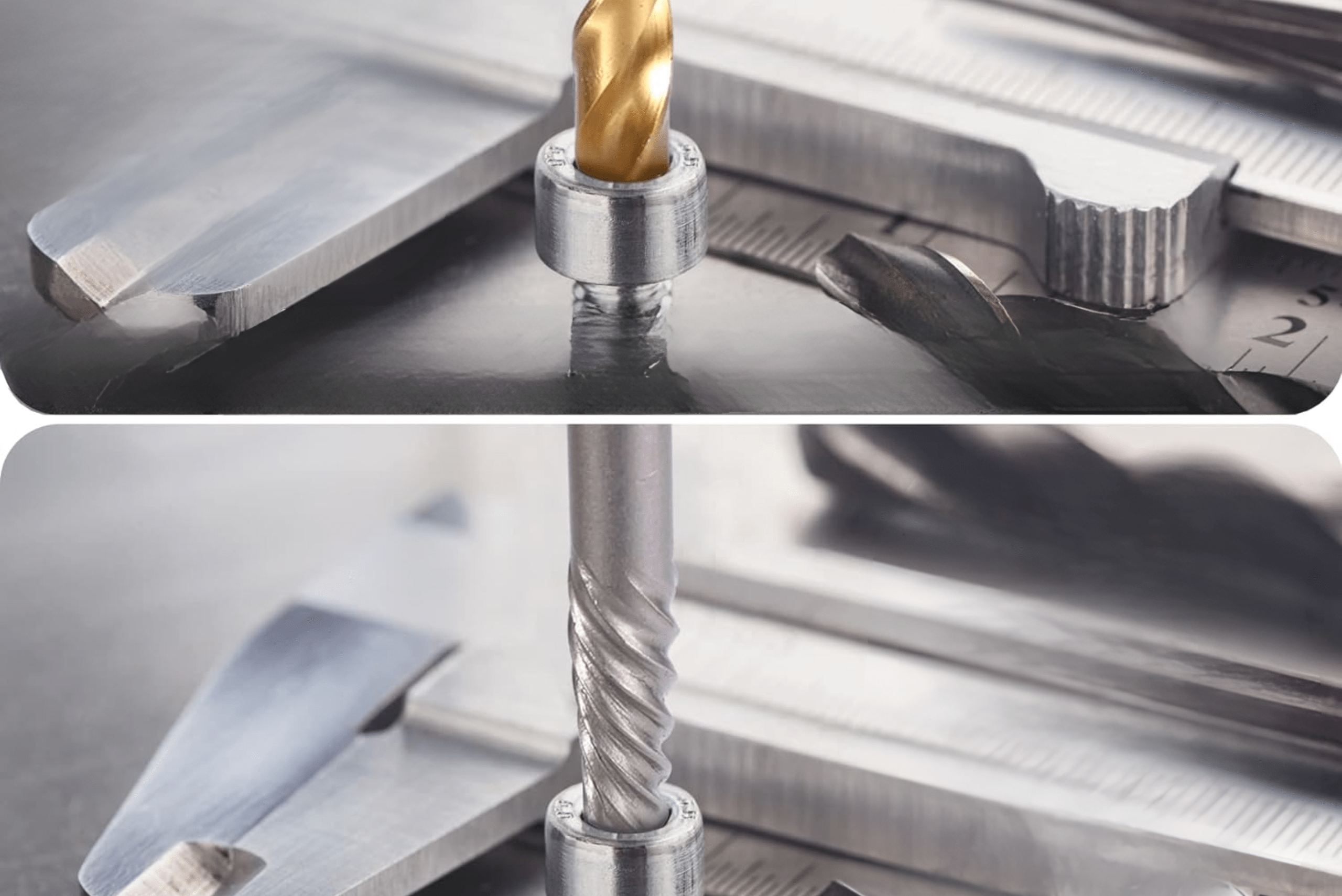

First, understand that screw extractors come in different shapes and sizes, designed to handle various types of screws and bolts. The most common types are spiral-fluted extractors, which are ideal for removing screws with stripped heads, and straight-fluted extractors, better suited for screws that have broken off flush with the surface.

When you’re ready to select a screw extractor, consider the size and depth of the damaged screw. A smaller extractor would be necessary for precision electronics or jewelry, while larger, more robust extractors are better suited for automotive or construction tasks.

The key when figuring out how to use a screw extractor effectively starts with choosing the right one; this ensures that you can grip the damaged screw securely and apply the necessary torque to remove it without slipping or damaging the surrounding area further. Always match the extractor size closely with the screw to ensure a snug fit and efficient removal.

Necessary Tools and Materials for Using a Screw Extractor

When planning to remove a broken or stripped screw, having the right tools and materials is crucial for a successful outcome. The central item you’ll need is a screw extractor set, which typically includes extractors of various sizes to match the screw you are dealing with.

Alongside the screw extractor, it’s essential to have a variable-speed drill. The ability to control the drill speed is important as it helps prevent further damage to the material surrounding the screw. A set of left-handed drill bits can also be beneficial, as they can help loosen the screw while you drill. Additionally, having a center punch will help you make a guide hole in the exact center of the screw, ensuring the extractor’s efficiency.

Penetrating oil can be very useful for lubricating the screw, making the extraction process smoother and less likely to cause additional damage.

Safety goggles should be worn to protect your eyes from any metal filings or debris that might be dislodged during the process. Lastly, having a hammer might be necessary to tap the extractor into place. With these tools and materials ready, you can approach the task with confidence, knowing you’re prepared to handle the job efficiently and safely.

Step-by-Step Guide on How to Use a Screw Extractor

Step One

First, you’ll need to select the appropriate size of screw extractor, which should fit snugly into the head of your damaged screw. Start by drilling a pilot hole into the top of the screw to give the extractor a guide. It’s crucial to drill slowly and carefully to ensure the hole is centered; otherwise, the extractor might not grip properly.

Step Two

Once the pilot hole is ready, insert the screw extractor into the hole and turn it counterclockwise using a hand drill or a T-handle. The extractor’s threads are designed to bite into the metal as you turn, increasing traction and gradually loosening the screw until it comes free from the material.

Helpful Tip: Patience is key here; applying too much force can cause the extractor to break, leaving you with a bigger headache. If the screw proves stubborn, applying penetrating oil around the screw beforehand can help by breaking down any corrosion and aiding its grip.

Tips to Prevent Breaking or Damaging the Screw Further

When faced with a stubborn screw that just won’t budge, reaching for a screw extractor can seem like an obvious choice. However, to avoid further damaging or breaking the screw, it’s crucial to prepare adequately before attempting any extraction.

Start by ensuring the work area is well-lit and clean. Any debris, dirt, or obstructions can complicate the extraction process and increase the risk of tool slippage or screw damage.

It’s also wise to apply penetrating oil around the screw head well in advance, giving it ample time to work its way into the threads and loosen the bond caused by rust or over-torquing.

When using the screw extractor, apply steady and gentle pressure to avoid snapping the screw shaft. Turning the extractor too forcefully or at an incorrect angle can exacerbate the situation.

Related Articles

- Tips and Tricks For Removing a Stripped Allen Screw Easily

- How to Unscrew a Tight Screw and Deal with Stubborn Fasteners

- Stripped Screw Hacks – Effortless Solutions for Stubborn Screws

Whether you’re refurbishing old furniture, fixing automotive parts, or repairing electronic devices, the ability to swiftly and effectively remove damaged screws is invaluable. Thus, by integrating screw extractors into your toolkit, you not only solve immediate problems but also enhance your overall capability as a DIY enthusiast.

Frequently Asked Questions (FAQs)

What is a screw extractor, and how does it work?

A screw extractor is a tool designed to remove broken or stripped screws. It works by drilling a pilot hole into the screw’s center, then a specialized bit is inserted and turned counterclockwise. The extractor’s tapered shape and sharp threads grip into the sides of the drilled hole, allowing the user to extract the screw.

What types of screw extractors are there?

There are mainly two types of screw extractors: spiral flute extractors and straight flute extractors. Spiral flute extractors are ideal for removing fasteners in softer materials, as they provide extra gripping power. Straight flute extractors are better suited for harder materials, as they prevent the extractor from expanding and getting stuck in the material.

How do I choose the right size screw extractor?

The size of the screw extractor you need depends on the size of the screw you are trying to remove. Most screw extractor sets come with a guide or chart that matches the extractor size with the screw size. As a general rule, choose an extractor that is slightly smaller than the screw’s diameter to ensure a tight fit.

How do I prepare the screw for extraction?

Before using a screw extractor, it’s important to drill a pilot hole into the center of the screw. Use a drill bit that is slightly smaller than the screw’s core diameter. This hole will guide the screw extractor and help it grip the screw more effectively.

Can I use a screw extractor on any material?

Screw extractors can be used on a variety of materials, including wood, metal, and plastic. However, the effectiveness can vary depending on the material’s hardness and the condition of the screw. It’s important to proceed with caution and use the appropriate extractor type for the material.

What should I do if the screw extractor doesn’t work?

If the screw extractor fails to remove the screw, it could be due to several reasons, such as using the wrong size extractor, not drilling the pilot hole properly, or the screw being too tight. You can try drilling a deeper pilot hole or using a larger extractor. If these methods fail, consider seeking professional help or using alternative methods like drilling out the screw completely.

How do I care for my screw extractors?

To ensure longevity and maintain effectiveness, clean your screw extractors after each use. Store them in a dry place to prevent rust and corrosion. Avoid using them on screws that are too large or too tight for the extractor size, as this can damage the tool. Sharpening the extractors periodically can also help maintain their gripping power.