Mastering Sawzall: Essential Tips and Techniques

The nickname around the workplace for the Sawzall by many carpenters is “God’s power tool.” The versatile tool has a relatively short history when compared to traditional saws, which can trace the lineage back to the Bronze Age.

Reciprocating saws (the generic name for the Sawzall) were first introduced during World War II. These specialty saws were heavy in comparison to the modern Sawzall and were designed for quickly ripping apart standing walls, floors, beams, and all the other construction materials found on a salvage job.

The Ultimate Tool, The Sawzall

The basic function of the reciprocating saw hasn’t changed, though the design has evolved in step with technology. Cordless models, lightweight plastic housings, and quick-release blades have been game changers.

The Sawzall is perhaps the most intimidating power tool on the market, but it’s easy to tame this tiger of a tool if you learn how.

Choosing the Right Blade For Your Sawzall

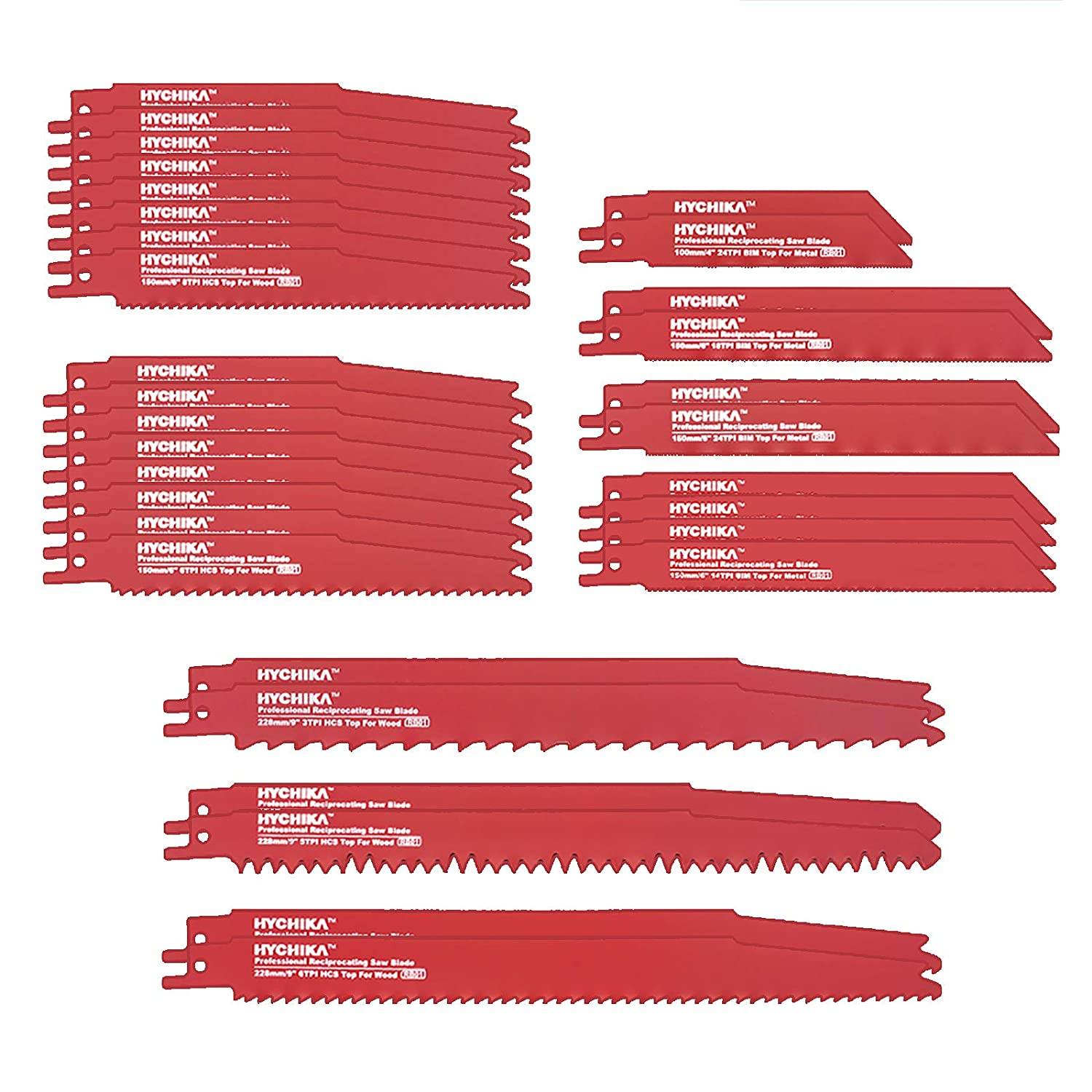

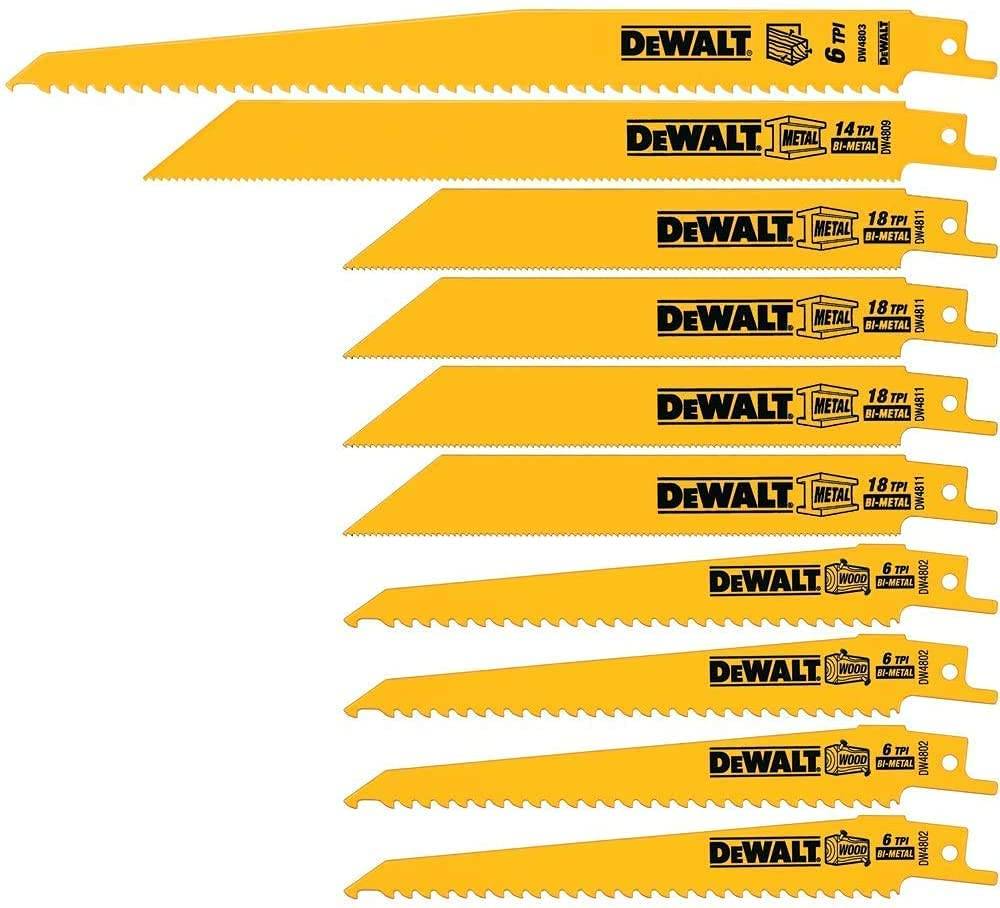

The first thing to determine when using a Sawzall is which type of blade you need with it. There are thousands of blades available. Some are designed for fine cuts, as you’d find in cutting plywood, while others have much more aggressive teeth with no finesse at all, but they can tear through a log almost as well as a chainsaw.

Some blades are designed for metal and not just one type of metal. Ferrous blades are harder and are designed to cut steel and cast iron. Plumbers use a finer blade for cutting copper pipes, and electricians use a combination metal blades when gutting existing coated copper and aluminum wires.

DIY-Friendly Sawzall Blades

For the weekend warrior, the best blade is usually a combination that allows the user to cut wood and soft metal without changing blades.

The length of the blade is another choice in using a Sawzall. The blades can vary from just three inches to something that looks like it came out of a medieval war with an 18-inch, heavy-toothed blade. However, if you are not often taking on projects with your sawzall, get a general blade with a medium length.

The Cuts Possible Using a Sawzall

Standard cuts, plunge cuts, and angled cuts are the most popular ways of using a Sawzall. A standard cut starts just as you would with a handsaw or hacksaw. Place the blade lighting on the target and pull the trigger. A Sawzall has speed-adjustable tension, meaning the harder you pull the trigger, the faster the blade will move. Start with a light touch until you have a small groove established, then fully pull the trigger to watch the saw finish the job.

Perhaps one of the best uses of the Sawzall is in plunge cuts. Lay the saw blade on top of a flat surface such as a roof, patio deck, or sheet of plywood. The saw will be almost parallel to the wood you’re about to cut. Squeeze the trigger lightly and let the saw cut a groove into the material. As the cut begins to deepen, lift the rear of the saw slightly. This will create an angle in the cut. Keep lifting lightly until the saw blade cuts through the material entirely. At this point, you can lift the saw to a perpendicular angle with the material and cut normally.

This method works very well with sheetrock, too. In the hands of a skilled user, it can cut outlines for electrical boxes, light fixtures, and holes that fit around obstacles in a wall.

The final method is an angle cut. It might be a flat cut for removing standing 2×4 studs from a wall you’re demolishing, it could be an angled cut at 45 degrees to create an opening for moving equipment and material into a tight space or something in between.

Safety First When Using A Sawzall

A caveat for this tool is how quickly it can work. As a young carpenter, I was working with a summer crew assigned to tear down an old porch and install a new one in its place. The foreman told me he had traced the electric wires on the porch, determining they were either clear of the path or had to be removed.

I snapped a chalk line and started cutting along the metal flashing of the porch roof through two layers of asphalt shingles. The saw ripped easily across the surface but suddenly came to a stop. I’d cut right through a hot 12 gauge wire, shutting off the power to the saw. No sparks, no shock, just a severed wire, and no power. The saw was that fast.

I hooked the extension cord to another outlet, finished the job, and repaired the power line.