How to Unwarp Wood – Efficient Restoration Tips

Wood can be a beautiful material that has multiple uses. The one major issue with using wood as your primary material is that it could potentially warp. Warping is where the shape of the wood changes shape over time, also compromising the structural integrity.

What you may not know is just how wood winds up warping. In this guide, you will learn not only what causes wood warping but how to prevent and even fix it should it be a current issue. Salvage that damaged wood and save yourself a few dollars (and hassles) along the way.

What Causes Wood to Warp?

The primary reason that wood warps is due to moisture. Moisture is the bane of existence for building materials but it has the kind of impact on wood that becomes noticeable immediately. Even a little bit of moisture, given enough time, can cause wood to warp.

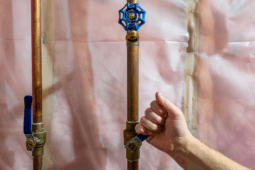

Moisture

Identifying areas where leaks are possible is the first step toward preventing them from happening. Leaks that can’t be seen oftentimes go unnoticed, leading to warping. It is always easier to address the problem beforehand rather than have to fix damaged or warped wood.

Moisture seeps into the wood and ultimately dries out unevenly. It is this process that causes the wood to shift, which creates the bowing effect. Too much moisture and the wood will not only warp but eventually rot. When wood rot has set in, there may be no coming back for that piece of wood. Replacing it and eliminating the problem becomes crucial.

Wood quality

Sometimes, you can take all of the necessary precautions and still find yourself with warped wood. What you may not have realized is that lower-quality wood can be easily impacted by outside forces that lead to warping.

Contrary to popular belief, cost is not the only way to determine the quality of wood. That actually depends on where the wood is sourced from as well as how it’s cut. Do your homework on the different types of wood available and you can save yourself a lot of trouble when it comes to warping.

Insects

Though most insects are of no threat to your building materials, there are some that can be detrimental to your wood boards. These insects attack the very fiber of the wood, which is what causes it to bend. Beetles and ants are the most common offenders, boring into the wood and clearing large chunks out in short order.

Depending on where you store your wood, make sure that you take precautions against insects. Despite their size, they can cause massive problems by degrading the structural integrity of your wood and causing it to bow and warp.

Improper storage

While moisture is typically the top reason for wood warping, it can also be narrowed down to bad storage. Don’t just throw your wood boards anywhere they might fit. They need to be laid out flat and on an elevated surface if possible. People tend to store their wood boards standing up and experience warping because the fiber within is trying to stabilize itself.

Improper storage can also lead to other issues. Bugs may have easier access, allowing them to do damage. Keeping boards on the ground also leaves them susceptible to potential moisture damage. Take the time to properly store your boards and you should be able to avoid any potential warping issues.

In What Ways Does Wood Warp?

In addition to knowing why wood warps, it helps to know the various ways in which wood can potentially warp. After all, you need to enter into the situation with as much information as possible so that you can implement the proper fix.

There are five ways in which wood can typically warp. It can crook, kink, bow, cup, and twist. Let’s dive a little deeper to see what each of these means so that you can spot the particular type of bowing that may be plaguing you.

Crook. Crooking happens at the length of the edge of the board. Typically, you won’t see warping consistently throughout the board, more along a specific measurement or edge. That is the case with crooking.

Kink. Kinking happens along the width of the wood and generally doesn’t have as broad of coverage as you would find from cupping and twisting. Still, it can create imperfections along the edges that take away from the overall aesthetic.

Bow. Bowing takes place primarily along the length of the face of the board. This can be a little more difficult to spot unless you are looking closely.

Cup. Cupping occurs when the width edges start to become misaligned with the center of the face. Cupping can move in either direction but it becomes apparent that the edges are not in line with the center.

Twist. Twisting happens when the corners begin to shift. Ultimately, this makes the board unable to lay totally flat as it is supposed to.

How to Flatten Warped Wood

So, you have noticed that the wood you were going to work with is warped. Don’t worry, though, as it isn’t the end of the world. Don’t let warping, even in small spots, persist for any longer than you need to. Take care of it immediately and ensure that it does not spread. If the warping is not too extreme, then it is indeed possible to flatten out and fix the wood.

Each board will need to be assessed individually so as to determine whether it can be fixed and flattened out. Experienced woodworkers know how to straighten warped wood, and now you can too. Here are a few tips for flattening wood that has already experienced a bit of warping.

1.) Sunlight

Exposure to sunlight can be both bad and good for wood boards. It all depends on how that exposure is being handled. If you are looking to straighten out your wood boards, you can use the power of sunlight to achieve the results. That said, this is perhaps the most time-costly option to choose. If you don’t have a ton of patience or need to get a faster fix, then exposure to sunlight is probably not going to be the right option for you.

Begin by taking a towel and soaking it in water. Make sure to squeeze out as much of the excess moisture as you can because you don’t want too much getting down into the fibers of the wood. Wrap your warped wood with the towel and let it sit in constant sunlight. Give it as many as four days to get the job done. The moisture will seep into the board and then dry up, allowing the board to settle into a flatter state. If you are dealing with kink warping, this method is the best option to choose.

2.) Moisture and steam

Perhaps the most common method of flattening out warped wood is through the use of moisture and steam. Think about it like this: moisture and heat can cause the wood to warp, right? Well, it turns out that it can be used to unwarp the wood as well. If you choose this method, make sure that you heat the wood lightly for around 10 or 15 minutes. Getting too close to the heat or using too much can do additional damage to the boards.

As you heat the wood, add a little bit of moisture, being careful not to overdo it. The heat allows the wood to properly absorb the moisture, making the wood flexible again. When the wood regains its flexibility, it can be bent back into its original shape. Gently straighten any of the bent areas, using clamps against a flat space to hold them in place. The wood will then dry into a flat shape. This is particularly effective if you are dealing with bowing boards.

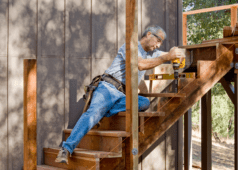

3.) Use a jack plane

For those dealing with cupping issues, a jack plane may be the best method to choose. It can be effective with other types of warping but may not have quite the impact as it would against a board that has suffered cupping.

The process of jack planning involves removing a part of that bent area using the jack plane. This, in turn, straightens out the surface. The caveat here is that you have to be careful. Those who are not familiar with using a jack plane can take too much of the wood up, weakening it in the process. The use of a jack plane is probably best left to woodworkers or very experienced DIYers.

4.) Apply pressure

Another great way to undo the warping to your wood boards is to apply pressure. The key is to make sure that you apply that pressure in the right areas and over a longer period of time. Should you choose to go with this method, start by getting a few damp paper towels and place them over the warped area. Carefully wrap the remainder of the board to prevent any moisture from crossing over.

After perhaps a few hours, you can remove the plastic covering from the board. Move the wood to a flat surface, preferably a table. Use clamps to hold the board down, and then begin applying heat only to the impacted areas. You may have to do this over several days to get the board to properly flatten. When you are confident that the board has been flattened, you can then remove the clamps.

5.) Use an iron

The final method involves utilizing an iron. While it is probably one of the more unorthodox methods you will find, it can be quite an effective way of straightening out a warped piece of wood. Like any other method, just make sure that you proceed with caution. For this process, you need a pressing iron, an ironing table, and a wet piece of towel or cloth. You can substitute the ironing table with a flat, stable surface if need be.

Start by soaking your cloth or towel in water and squeezing out all of the excess water. You want it to be damp, not soaking wet. Use your towel to cover the entirety of the warped surface area, putting it down on your flat surface. Heat the iron and press it down on the towel. Do this repeatedly until you see that the wood is beginning to flatten out. Clamp the board down and give it time to dry, which should retain its straight composition.

How to Prevent Wood from Warping

It is always better to prevent wood from warping rather than having to try to fix it. Getting ahead of the issue can make it easier to take care of the wood board and ensure that it looks and performs at its best. The good news is that there are a variety of ways in which you can keep your wood from warping. The first is to ensure that it is stored in proper conditions. Yes, you can warp wood before it ever gets installed.

The storage conditions can play a major role in the warping of wood. Exposure to UV rays, high temperatures, and humidity will alter thinly cut wood rather easily. Make sure that you keep wood in an area that is both cool and dry. Do not allow for direct sunlight exposure, and ensure that the area is well-ventilated. Finally, make sure that you keep each board lying flat. If possible, keep them slightly off the ground to prevent any possible water damage, and put weights on the boards to keep them as straight as possible.

Wood Coating

Another great way to keep wood from warping is to protect it against water and heat. Since those are the two most responsible factors, having a moisture-proof coating can go a long way toward protecting against warping.

Coat the surface of your wood boards using some kind of wood finish. Oil-based paints and polyurethane are great solutions because they basically insulate the surface of the wood. This prevents both water and heat from getting into the fibers and affecting the wood. Even better, it can improve the aesthetic quality of the wood as well.

Helpful Tips for Straightening Wood that Has Warped

First of all, start by being safe. Wear protective equipment, particularly gloves and/or goggles. Gloves are most important so long as they have heat-resistant properties. You will likely need to involve heat of some form and the surface of the boards can get quite hot, making them difficult to handle with your bare hands.

Patience is also crucial for straightening warped wood. Some of these methods take quite a bit of time to properly execute. By trying to rush through or lacking patience, you may not only fail in unwarping the wood but could potentially do further damage to it. With enough damage done, you will need to replace the boards entirely.

Finally, it helps to know what type of wood and warping you are dealing with. Don’t just use any old method, as they may not be quite as effective as you had hoped. Choosing the right method can help improve the chances that you get the proper results.